Web Site by cg-photohraphy.co.uk

When is a project not a project? When it’s not completed, right?

This project came about after seeing the video below, from Cyclops Designs:

Cyclops Designs Plasma Guillotine

Project Date: 8 July 2018

Using a plasma cutter is easy, just hold it 1mm over the metal you want to cut and hey presto!

Well sort of. The plasma gun the I have does have a guard that will keep this distance but is not that solid with it’s mount. See below:

This is the Trafimet ERGOCUT S45 gun as fitted to my Cros-Arc 40.

This gun does have another trick up it’s sleeve, and that is a gouging tip that drag cuts. So you don’t always need that standoff.

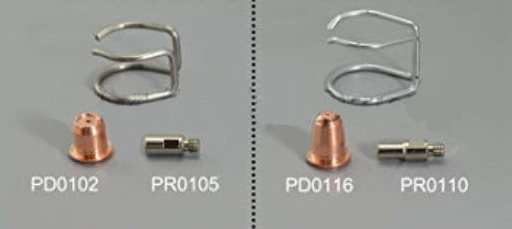

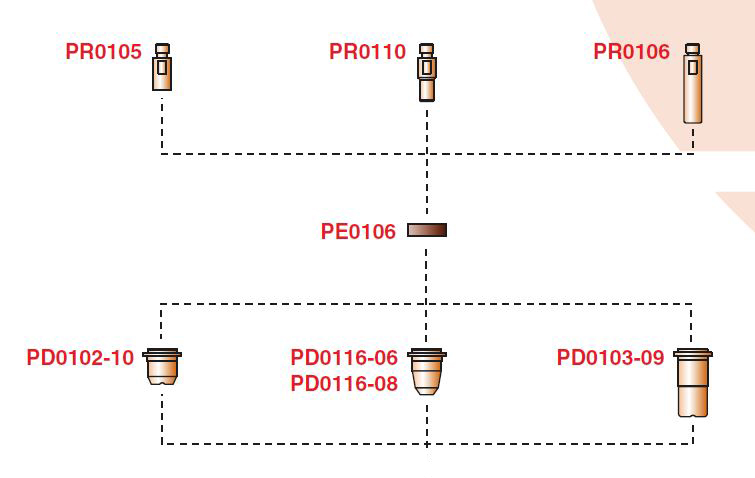

Drag Tip

Standard Tip

So what have we seen so far?

For best cutting results, and extending the life of the consumables, fit the wire guide and keep the cutting tip 1mm from the surface of the metal you are cutting.

Switch to the drag tip, this tip design gives the air and some of the dross a place to escape via those grooves in the tip, especially when cutting using a template.

However, what if you could cut a straight line, and keep the cutting tip a constant distance from the metal that you are cutting?

That is exactly what the Cyclops Plasma Guillotine does, so I purchased one, and what a beast, the sides alone are made from ½ steel plate, the weight is incredible.

There was also one other problem, the front plate that holds the cutting torch, was made for a much larger torch that the Trafimet S45, and so would not fit.

However, a quick call to Tom at Cyclops and he sent me a new front plate without the torch part attached.

As you can see the standard supplied front bracket is no good for this Trafimet torch.

This is the new front bracket that Tom supplied. As you can see the ‘torch tube’ is missing, which means I can fabricate my own.

and here it is;

I turned this one up on the lathe. It is a direct copy of the ‘head’ from my plasma circle cutter that was specifically made for my Trafimet torch.

Notice the bottom part of the holder, I turned this precisely to the hole that I re-cut in the front mounting plate, in the previous picture.

In this way both parts will line up and stay perfectly square when tack welded together.

The two parts placed together, with a spare Trafimet S45 head, all I need to do is drill and tap for a couple of ‘wing knobs’ which will hold the torch in place.

I need to fit two of these ‘wing knobs’ to finish the front plate.

Just when you thought the project had some normality about it, I found the video below:

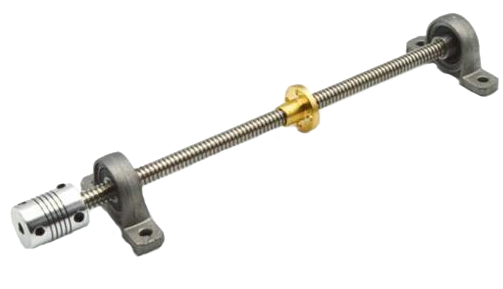

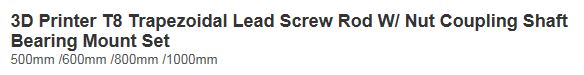

So how about if I add this power train to my Plasma Guillotine, and than add a laser for alignment?

See below some of the parts that I am thinking of using:

You will have to wait and see as this project is currently stored in my loft, all 30kgs of it.

How did I get it into my loft? using the Electric Loft Hoist, from the projects section.

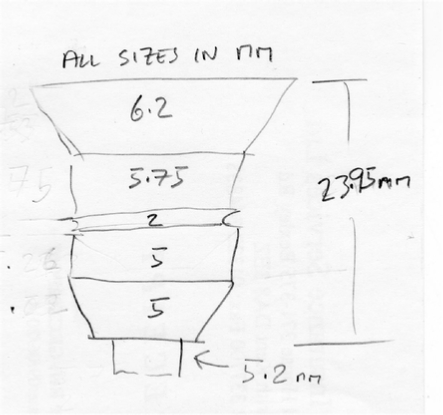

These are the dimensions of the cutting head on the Trafimet S45 torch.

| Rage 3 Saw |

| ESAB Welder |

| Cros-Arc Plasma |

| HHO |

| Spot Welding |

| Betty's Gates |

| Car Headlights |

| Julia's Dartboard |

| Outside Light Base |

| Weather Vane |

| Geoff's Gates |

| Loft Hoist |

| Colin Laser Mount |