Web Site by cg-photohraphy.co.uk

This page is about a one ton arbor press, but why I needed it in the first place, is more important?

I work in a residential neighbourhood, in my garage workshop in fact. So I need to keep the noise down. A lot of my neighbours are like myself retired, and the last thing they need is someone that makes a lot of noise.

Isn’t that true of us all?

When I started out I used an angle grinder, with some flap discs, this spins at about 10,000rpm, and to be honest, not only makes a lot of racket but is a little unwieldy to control. It’s also nearly impossible to get into all of those small spaces.

So needed to find an alternative.

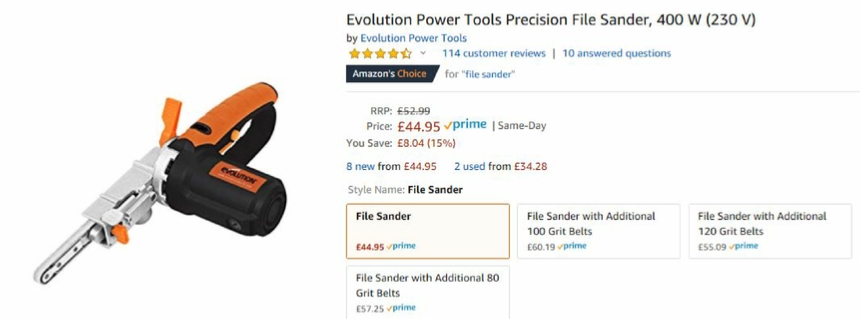

This is what I found, the Evolution File Sander.

One Ton Arbor Press and Dies

So let me say ‘right-off-the-bat’, some people knock Evolution tools, by comparing them with makes such as DeWalt. You simply can’t do that, Evolution tools I think come in at a price point for the home or hobby user like me, and maybe you?

You cannot compare tools that cost £600 with one that costs £100. So you have to accept some compromise!

I purchased the file from Amazon like I do with a lot of my tools, and so far so good. I know that I would be primarily working with steel, and not wood, which this tool and it’s aluminium brown belts were designed for.

So I needed to ditch the brown aluminium oxide belts, and look for something better.

Now this is very important, and we shall touch on this subject again on the Belt Sander Pulley Modification page, so stay tuned!

What I found was Zirconia Sanding Belts, why? well the material is harder that steel. Take a look below:

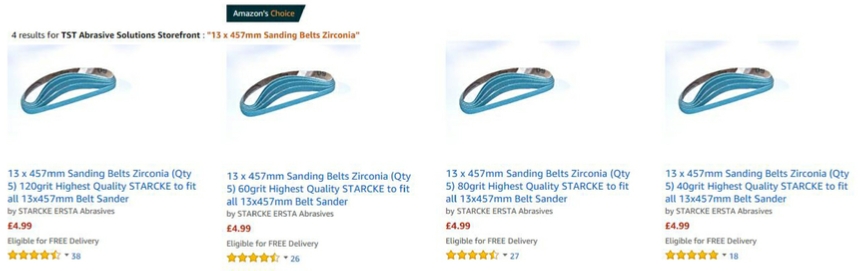

Zirconia Sanding Belts are available in a number of different grit types, see below:

I found these on Amazon and I have purchased several sets of them from TST Abrasive Solutions and can recommend them.

The Evolution file sander has a variable speed, and is perfect for removing mill scale before welding. It is also much quieter, and far more controllable, that an angle grinder.

So I purchased those Zirconia belts and got to work, and all with the world was good….

Except after a couple of weeks, belts broke and whizzed off at angles while I was trying to use it.

What was going on?

The picture on the right is the business end of the file. The belt goes over the two wheels.

What I found was that with extended use the bearings had partially seized, causing the wheels to stop rotating and the belts to fly off, I suspect because of the heat caused by the friction.

Now I did get in contact with Evolution, and they were very helpful, in fact there sent me FOC another front end wheel unit. This worked for another length of time and then had the same problem!

So I now had a choice, I have a electric file tool that I liked, but it had a problem.

I could just abandon the Evolution unit and go and find another manufacturer, (like Makita who also make one), or try and fix this situation, which would be more fun and hopefully another learning experience!

If you look at the picture above you will see that the bearing wheels are held in on pins that are an interference fit or simply, (to be not technical) ‘pushed in’.

Now it’s taken a long time to get here, but do you now see the need for that press!!!!!!!!

Back to my favourite shop Machine Mart, who were advertising Half, One and Two Ton presses.

Prices are ½ Ton £38.39 inc Vat

1 Ton £59.98 inc Vat

2 Ton £214.99 inc Vat

You can view the technical manual here:

I decided to purchase the 1 Ton version, as the larger 2 Ton press was too large, too heavy and too expensive.

I also found this video and decided to carry out this modification on my Press.

This modification made a lot of sense to me. As when you use a press you really need to ‘pull down’. This mod allows you to get the handle to where you need it.

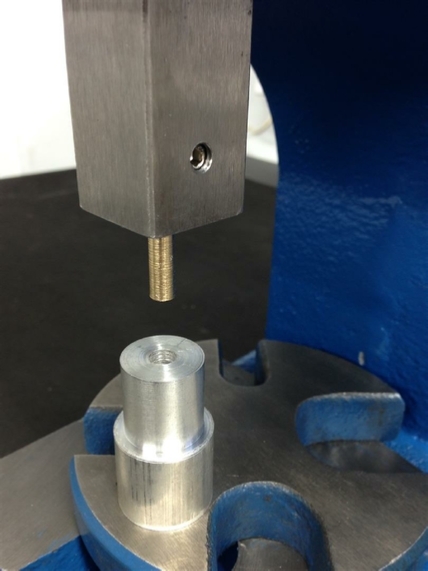

The other thing a lot of people want from their press is the ability to ‘hold’ the ‘punch’ in ram. To do this you need to drill a hole in centre of the ram arm. You will also have to drill and tap some holes at right angles to position some grub screws to hold the ‘punch’ in place in the ram as you use it.

The other thing that I did, was turn in the lathe a short steel ‘punch’, to fill the hole in the ram. So that I would have a completely flat ram base. I think that this is essential, as anything less would compromise the use of the press, for general use.

So just to be sure:

The Punch fits into the ram.

and

The Die fits into the table.

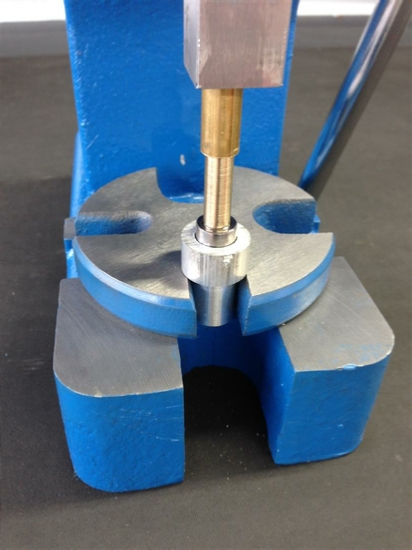

See the pictures below:

Notice the teeth that I cut out of the ram, as per the video above. Also note my cobalt drill in action, I think I used 10mm. I wasn't sure what the ram was made of, but that drill made short work of it.

This picture shows one of those Evolution wheels having the bearing removed using the punch and die that I made. See the diagram notes that I made at the time for any dimensions.

This picture shows the steel wheels and the bearings. This was the first punch and the die that I made.

This picture shows the grub screws now fitted to the ram along with a hole drilled into the table to better fit a second die that I made.

This die locates into the hole in the table to give a precise lock between the punch and the die. The punch is now held in place by those grub screws so can’t fall out.

To replace the Evolution bearings is a two part operation, first push the interference pin out of the wheel carrier, second push the bearing out of the steel roller wheel. Then do the reverse to complete the job.

Using the press I can normally do the whole operation in a couple of minutes max. I now have three wheel assemblies from Evolution-uk they are about £10 each inc p&p.

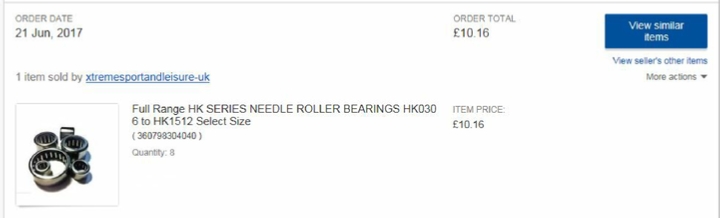

I just wait for one to start making a noise, and replace it, making sure to add some grease to the needle roller bearings before putting it back together.

The bearings were from Ebay and are type HK 0608 6x10x8 mm See Below:

Back to Top

Back to Top

Project Date: 23 June 2017

| Rage 3 Saw |

| ESAB Welder |

| Cros-Arc Plasma |

| HHO |

| Spot Welding |

| Betty's Gates |

| Car Headlights |

| Julia's Dartboard |

| Outside Light Base |

| Weather Vane |

| Geoff's Gates |

| Loft Hoist |

| Colin Laser Mount |