Web Site by cg-photohraphy.co.uk

This is where the story really begins clearing old bench in the workshop and waiting for the first metal order to arrive from The Metal Store in West Yorkshire Free Delivery £70 plus order, and free cuts up to tem per length. I have got to say these guys are excellent. Give them a try.

Metal Arrives & Drill Rollers

This order was all of the metal for the bench and the quick release mounts for things like vices and bench grinders. Order weight about 130kg.

So no light weight.

Click on the pictures on the left to look see.

I also needed to build some form of mounts to allow me to drill the bench components, especially as the front of the bench mount was going to be nearly 1.5Mtrs in length, and a depth of nearly 1Mtr.

The problem is that the pillar drill plate is only normally about 12” sq.

I already had two rollers stands. Could I somehow modify and use them?

The thing is, if you have three things, a welder, some steel, and a good idea!

You can do anything!

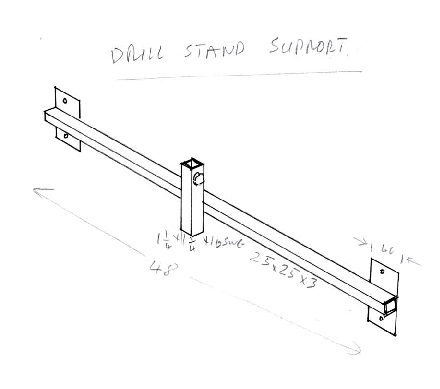

So my first idea was drawing above.

Incidentally, this was drawn using my 3D drawing board, just thought you would like to know?

The idea was to add a steel cross member to my drill bench, with a right angle tube to allow me to remove the top of the roller stand and lock it in place use a weldnut and star wheel. So this was the plan.

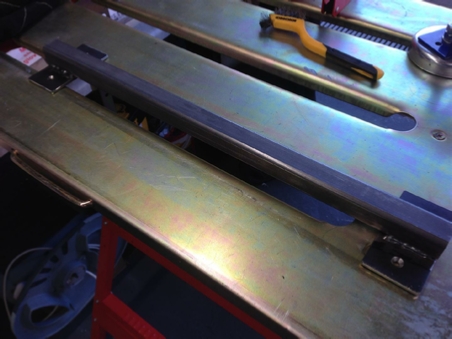

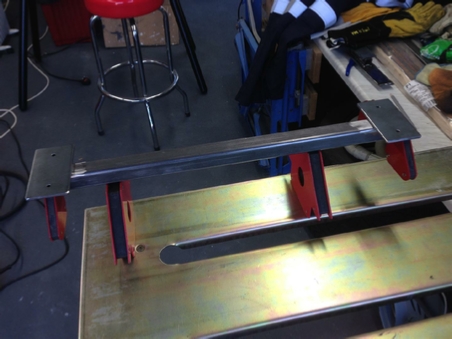

Cross member now cut and first screw plate made.

The screw plate was cut using my Cros-Arc plasma cutter.

Both end plates cut and checking alignment.

Parts cleaned up, and held in place with magnets.

Ready to go!

First welding done

Looks good!

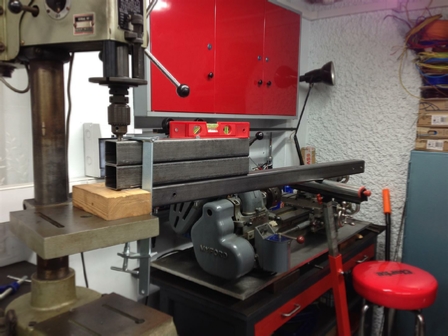

Screwed in place on the drill table.

Upright now added and held in place with the weldnut and star wheel.

This is just what I wanted a good solid support for the left hand side on the drill table.

Now this piece was created so that I could utilise the second roller stand, but this time to the right on the drill stand, where the lathe is.

This one has to be free standing, so this is just a height extender to get the roller up to the height of the drilling table.

This picture actually shows the front cross member of the bench being supported both from the left and the right. This is box section 60 x 50 x 5mm and is about 1.5Mtr in length.

It is heavy, and both stands performed perfectly.

Just make sure the workpiece is level, I use a spirit level to adjust both roller stand heights.

You do not want this to slide off the drilling table!

Another example of the roller stand is action. This time for the steel of my electric loft hoist.

Notice the sprit level in use, and the clamp, holding the steel in place before drilling any holes.

First project down, many more to go!

Project Date: 7 April 2017

Next Project

Next Project| Rage 3 Saw |

| ESAB Welder |

| Cros-Arc Plasma |

| HHO |

| Spot Welding |

| Betty's Gates |

| Car Headlights |

| Julia's Dartboard |

| Outside Light Base |

| Weather Vane |

| Geoff's Gates |

| Loft Hoist |

| Colin Laser Mount |