Web Site by cg-photohraphy.co.uk

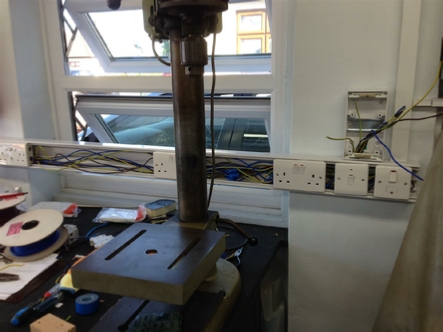

This is really the continuation of the electrical install. The lighting and back of the workshop had already been done, at this stage.

Electrics

Project Date: 21 May 2017

Parts and components ready to go.

You can see the two fuse boxes at the back of the workshop. I have a 6mm feed.

I decided to use 100mm dado trucking to hold all of the wiring, running 2.5mm for ring for power and 1.5mm for lighting.

Notice the separate fuse box above the two switch panels. This is especially for the plasma cutter, as its power requirements are greater than 13amps, if running at a maximum cutting current of 40amps.

The fuse box is 32amp on it’s own spur feeding a dedicated IP44 socket. See the Equipment/Cros-Arc Plasma page for full details.

This is where the bench is going to go.

Notice the blue IP44 socket for the Cros-Arc plasma cutter and the long alarm lead that will need shortening.

Also note the fire extinguisher on the wall, a very essential item to have when welding.

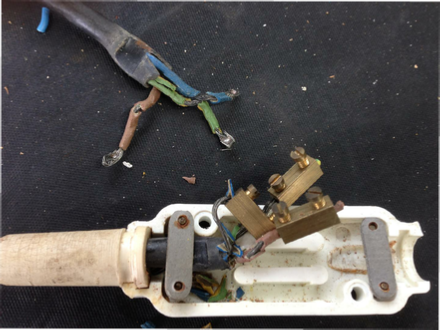

Now I found this, on the drill press extension lead. Clearly in need of replacement. However, I recommend all equipment in your workshop be PAT tested.

It could save your life!

I actually found this PAT tester on Ebay as a second user unit, but unused. £200 is a great price, as right now the retail price is about £310. (In 2019)

I used one at the School were I worked as a Network Manager. This unit is specifically designed for I.T. equipment. However, it is absolutely fine for all other equipment as well.

So I decided to get my own, especially as I still do I.T. At home.

I will be honest I have a bit of a love/hate relationship with PAT testing. I solemnly believe that the commercial insurance industry has got it wrong to require PAT testing of all portable equipment every year within a commercial premises.

Even the HSE have suggested that visual inspection on a day-to-day basis by an employee is sufficient. If you don’t believe me check out there link. ‘Myth: All office equipment must be tested once a year’

Just as a side note, after purchasing my Kewtech KT72, I checked all the portable electrical appliances in our house, my Mother’s house, and my partner’s Mother’s house. I did not find one single problem, not one.

The drill press extension lead issue above, was in fact found by me with a visual inspection only, strangely enough.

So I hear you asking ‘why did I buy a PAT tester then?’ Well I think it has it’s place. If you purchase a piece of equipment second user, test it. If you have a piece of equipment that you have had for a long time and you refurbish it, test it.

That is my advice.

| Rage 3 Saw |

| ESAB Welder |

| Cros-Arc Plasma |

| HHO |

| Spot Welding |

| Betty's Gates |

| Car Headlights |

| Julia's Dartboard |

| Outside Light Base |

| Weather Vane |

| Geoff's Gates |

| Loft Hoist |

| Colin Laser Mount |